-

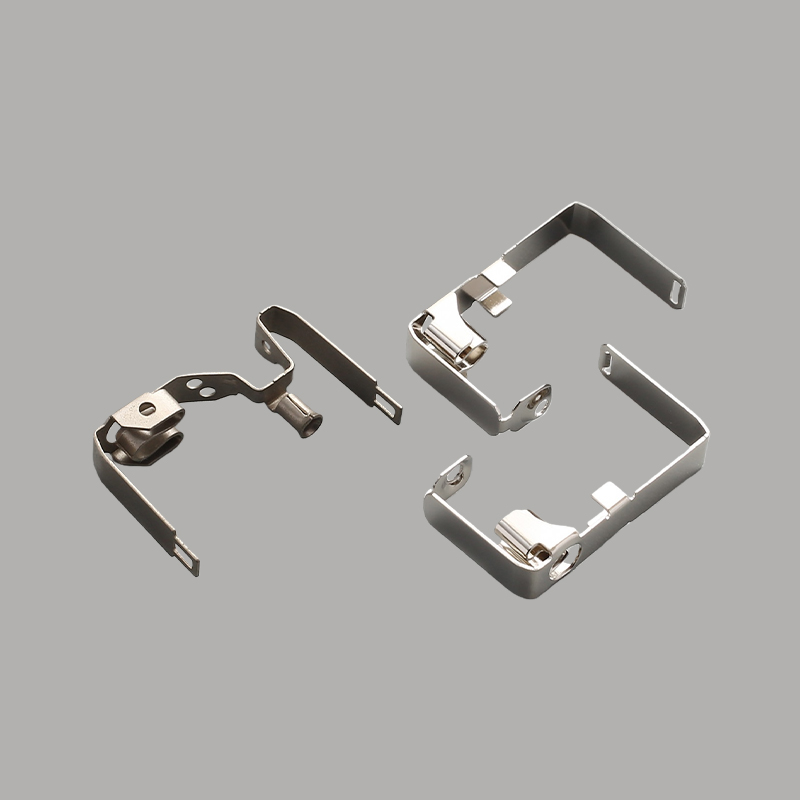

Copper Battery Spring Contact

Description:Brass contact manufacturer,Battery contact part,Contact copper,Brass spring electrical contacts,Spring contact,Electrical silver contacts,Copper battery spring contact,Electrical contact.

Send Email Details

Technical information:

1. Spring steel+Heat treatment+ Nickel/ Tin/ Silver/ Gold plating

2. Copper (brass, phosphor copper)+Nickel/ Tin/ Silver/ Gold plating

3. Beryllium copper+ heat treatment+ Nickel/ Tin/ Silver/ Gold plating

4. Stainless steel+ Nickel plating

Engineering difficulty:

1. Tiny size with precision dimension

2. Complex structure, with many bending

3. Assemble by soldering

Remarks:

1. Tooling time: 15 working days

2. Production time: 15 working days -

Battery Contacts

Description:Battery contacts,Tin plated copper contact,Battery spring,Contact copper,Spring contact,Battery contact part.

Send Email Details

Technical information:

1. Spring steel+Heat treatment+ Nickel/ Tin/ Silver/ Gold plating

2. Copper (brass, phosphor copper)+Nickel/ Tin/ Silver/ Gold plating

3. Beryllium copper+ heat treatment+ Nickel/ Tin/ Silver/ Gold plating

4. Stainless steel+ Nickel plating

Engineering difficulty:

1.Tiny size with precise dimension

Remarks:

1. Tooling time: 13 working days

2. Production time: 10 working days -

Brass Spring Electrical Contacts

Description:Brass spring electrical contacts,Smd battery contacts,Pcb battery contact,Electrical silver contacts,Custom spring contact,Custom made brass spring contacts.

Send Email Details

Technical information:

1. Spring steel+Heat treatment+ Nickel/ Tin/ Silver/ Gold plating

2. Copper (brass, phosphor copper)+Nickel/ Tin/ Silver/ Gold plating

3. Beryllium copper+ heat treatment+ Nickel/ Tin/ Silver/ Gold plating

4. Stainless steel+ Nickel plating

Engineering difficulty:

1. Various finish treatment options

2. Pass 72 hours salt spraying

Remarks:

1. Tooling time: 15 working days

2. Production time: 16 working days -

Electrical Contact

Description:Spring contact,Electrical contact.

Send Email Details

Technical information:

1. Material: Brass,

2. Surface treatment: Nickel plating,

3. Process: Progressive stamping --- Nickel plating

Engineering difficulty:

1. Size is small as 30*5*15 mm,

2. Structure is complex,

3. precision only accept +/-0.05mm tolerance.

Remarks:

1. Tooling time: 14 working days

2. Production time: 12 working days

3. Usage: security and fire prevention / Automatic remote control -

Terminal Connector

Description:Terminal connector,Connector terminal.

Send Email Details

Technical information:

1. Material: Spring steel,

2. Surface treatment: Nickel over copper plating,

3. Process: Progressive Stamping --- Heat treatment --- Nickel over copper plating

Engineering difficulty:

1. Usually nickel plating thickness is 3 to 5 μm, this part requires 8-10μm copper plating and 7-8μm nickel plating,

2. Should pass 24H salt spraying testing, without anti rust oil,

3. Very Elastic, side lips won't be broken after bended 90°oppositely.

4. Workable for high shear force, after soldered on PCB, won't be separated from PCB even apply 900N force.

Remarks:

1. Tooling time:12 working days

2. Production time: 12 working days

3. Usage: Electrical equipment / Video device / Voice controlled transmitter -

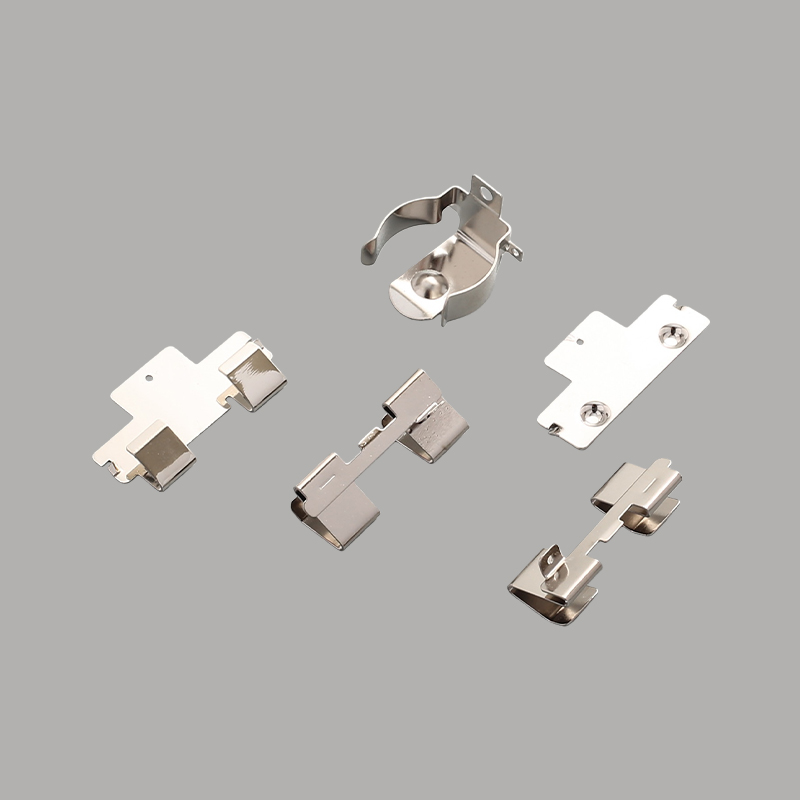

Electrical Silver Contacts

Description:Electrical silver contacts,Custom electrical contacts,Battery clip,Brass contact,Steel contact,Electric silver coppercontact plate,Pcb contact,Cmd battery contacts.

Send Email Details

Technical information:

1. Spring steel+Heat treatment+Nickel/Tin/Silver/Gold plating

2. Beryllium copper+ Heat treatment+ Nickel/ Tin/ Silver/ Gold plating

3. Stainless steel+ None/ Nickel plating

Engineering difficulty:

1. Tiny size with precision dimension

2. Concave structure on the small surface

3. Mask golden plating on some places

4. Assemble by riveting

Remarks:

1. Tooling time: 12 working days

2. Production time: 12 working days